To build a track

The

general building principle on our tracks has always been tracks sawn into 250

cm X 120 cm boards, using a circular saw for the straights and oscillating saw

for sharp corners.

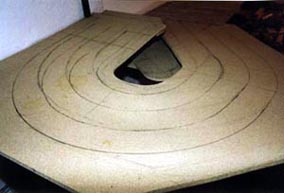

After

the initial layout is finished you cut off parts that will not be used.

Don´t make it too narrow in case you have to make small changes. Remember

run-off areas! As you can see we make run-offs uneven compared to the slots.

Otherwise we will be able to slide through the corner on full throttle.

And that´s no fun!

Strengthening is vital when cutting through the board with an oscillating

saw. However, this is necessary only att the very sharpest corners.

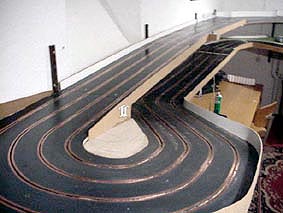

The slots are sawn and the whole thing is painted.

Mårten and Johan take some coffee. Very important!

Finished result! Wasn´t that quick?

The tracks are powered by 13,8 volts. Since we use dynamic braking the wiring is not that very simple, although rather straightforward if you´re just patient. Current is fed on the tracks through copper-tape of the kind used for window decorations. It´s cheap and simple to use. Motors more powerful than 16D-s require thicker copper or a braid. Because of the very small area of the coppertape it´s good to have several points where the copper is fed. You can get the copper tape from Teijlers Glas in Örebro.